Construct Wiser: Just How Aftermarket Construction Parts Can Boost Your Profits

Construct Wiser: Just How Aftermarket Construction Parts Can Boost Your Profits

Blog Article

Increase Effectiveness With Aftermarket Components: an Overview for Heavy Equipment Owners

Advantages of Aftermarket Components

Proprietors of heavy equipment can appreciate many advantages by deciding for aftermarket parts over initial devices manufacturer (OEM) components. Aftermarket components are commonly much more budget friendly than OEM parts, allowing equipment owners to minimize maintenance and fixing costs without compromising on quality.

Considering that aftermarket producers specialize in producing particular elements, equipment proprietors have accessibility to a broader range of choices to fit their requirements. Aftermarket parts are understood for their quality and reliability, with several meeting or surpassing OEM requirements.

Finally, choosing aftermarket parts can also lead to faster repair services and minimized downtime. With much easier availability and quick shipping options, equipment proprietors can obtain their tools up and running once again promptly, minimizing interruptions to their procedures.

Picking the Right Aftermarket Components

When considering aftermarket parts for heavy machinery, it is necessary to prioritize compatibility and high quality to ensure optimal performance and longevity of the tools. Choosing the ideal aftermarket parts can be a critical decision for heavy equipment proprietors as it directly impacts the performance and reliability of their equipment.

Secondly, quality should never be endangered when choosing aftermarket parts (aftermarket construction parts). Choosing for premium elements makes certain resilience, integrity, and total efficiency of the machinery. It is recommended to resource aftermarket components from respectable makers or suppliers known for their high quality requirements

Additionally, taking into consideration aspects such as service warranties, client reviews, and compatibility with existing systems can further assist in making the appropriate choice. By focusing on compatibility and quality when picking aftermarket components, heavy equipment proprietors can boost the performance and longevity of their devices.

Setup and Upkeep Tips

For efficient procedure and longevity of hefty machinery, correct installation and routine upkeep are paramount. When mounting aftermarket parts, make sure that you meticulously comply with the maker's directions to assure optimal efficiency. It is vital to utilize the correct devices and methods to avoid any damages throughout the installation process. Regular upkeep is crucial to keep your machinery running smoothly. Create an upkeep schedule that includes tasks such as checking fluid levels, checking for deterioration, and cleansing parts (aftermarket construction parts). Without delay attend to any kind of issues that arise to avoid further damage and costly repair services. Additionally, consider buying training for your maintenance personnel to guarantee they have the needed abilities to determine and address possible issues. By focusing on installment and upkeep treatments, you can make the most of the effectiveness and life expectancy of your heavy machinery, ultimately conserving time and money in the long run.

Cost-Effectiveness of Aftermarket Components

Proper setup and normal reference maintenance are fundamental aspects for heavy machinery owners intending to analyze the cost-effectiveness of aftermarket components for their tools. While original tools supplier (OEM) components are known for their high quality, aftermarket components offer a more cost-efficient solution without compromising performance. By meticulously reviewing the top quality and compatibility of aftermarket components with their equipment, owners can strike a balance between cost-effectiveness and efficiency, inevitably maximizing the performance and durability of their heavy equipment.

Making The Most Of Efficiency With Aftermarket Upgrades

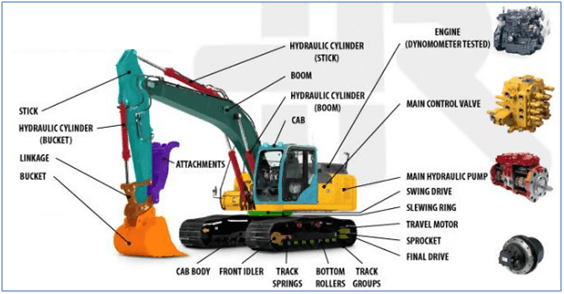

To boost functional performance and productivity, hefty machinery owners can effectively maximize performance via calculated usage of aftermarket upgrades. Aftermarket upgrades provide the possibility to customize heavy equipment to certain operational needs, resulting in boosted performance and output. Updating elements click this such as engines, transmissions, hydraulic systems, and tracks can substantially improve the total effectiveness of the machinery.

Consistently evaluating the efficiency of hefty machinery and determining locations where aftermarket upgrades can be advantageous is crucial for taking full advantage of performance. By purchasing high quality aftermarket components and upgrades, machinery proprietors can attain higher levels of effectiveness, ultimately resulting in set you back financial savings and improved operational results.

Conclusion

In conclusion, aftermarket parts use countless benefits for heavy machinery owners, consisting of cost-effectiveness, raised efficiency, and personalization choices. By picking the best aftermarket parts, adhering to correct installment and maintenance procedures, and taking full advantage of upgrades, hefty equipment proprietors can boost their devices's efficiency and long life. Investing in aftermarket parts can eventually cause boosted performance and decreased downtime, making it a beneficial factor to consider for proprietors her response aiming to optimize their machinery operations.

Owners of heavy machinery can delight in various benefits by choosing for aftermarket components over initial tools supplier (OEM) parts. Aftermarket parts are generally more affordable than OEM components, enabling machinery owners to reduce upkeep and fixing expenses without compromising on quality. By carefully reviewing the high quality and compatibility of aftermarket parts with their machinery, proprietors can strike an equilibrium between cost-effectiveness and efficiency, inevitably optimizing the effectiveness and longevity of their hefty devices.

In conclusion, aftermarket components provide numerous advantages for heavy machinery owners, including cost-effectiveness, enhanced efficiency, and personalization choices. By selecting the right aftermarket parts, complying with proper installment and maintenance treatments, and maximizing upgrades, hefty machinery proprietors can boost their devices's efficiency and durability.

Report this page